Tyres, the unsung heroes of our vehicles, are marvels of modern engineering. They play a pivotal role in ensuring safety, performance, and comfort during our journeys. But have you ever paused to ponder what goes into making these incredibly designed tools? Let’s embark on a journey to unravel the intricate anatomy of a tyre and its multifaceted components.

1. Tread: The Road’s Best Friend

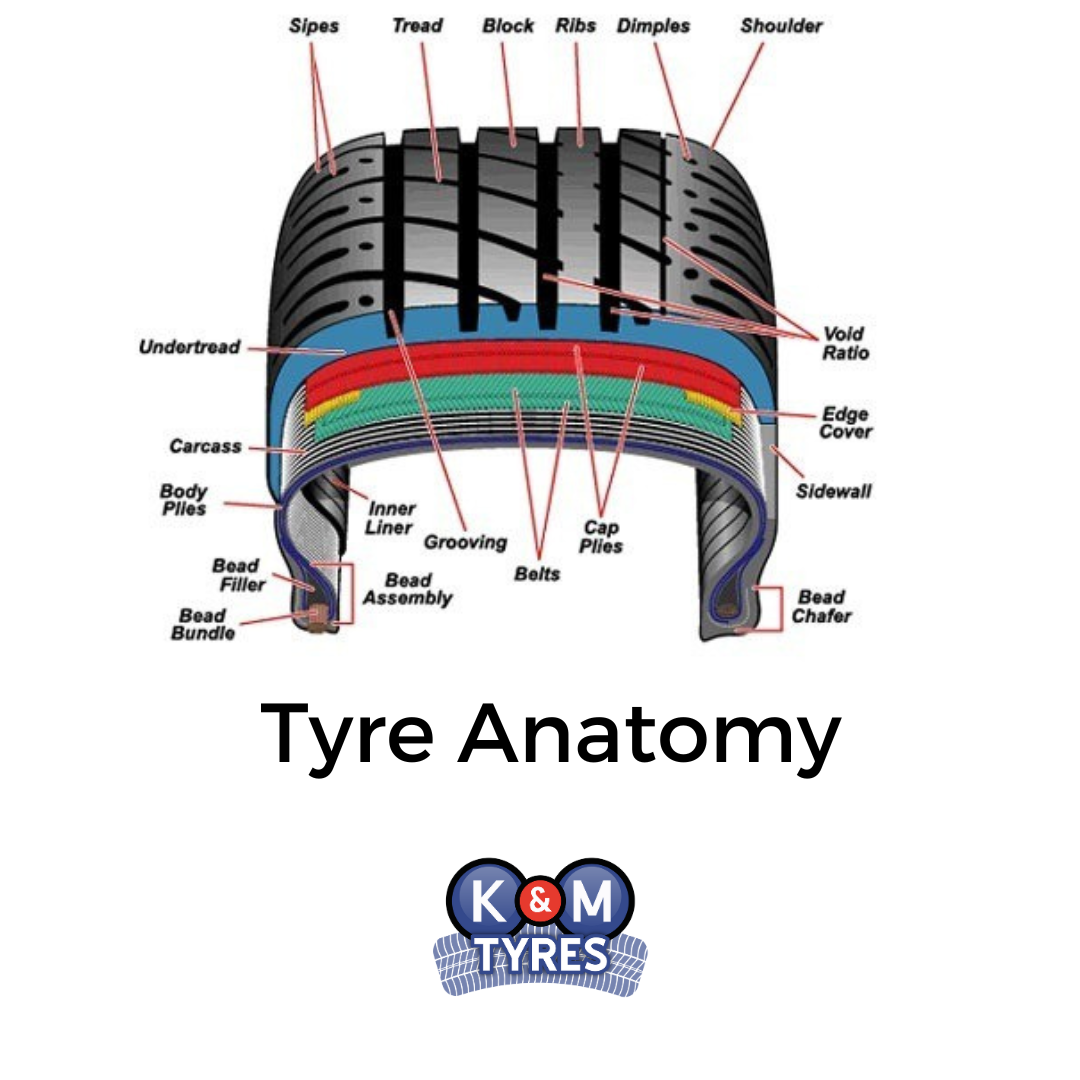

The tread, the outermost layer of the tyre, is the primary point of contact with the road. Its meticulously designed patterns not only provide the necessary grip for acceleration, braking, and cornering but also channel water away, significantly reducing the risk of aquaplaning during wet conditions.

2. Sidewall: The Protector and Informer

The sidewall, facing outwards, serves a dual purpose. It acts as a shield, protecting the tyre from potential side impacts. Additionally, it’s a treasure trove of information, displaying vital details such as tyre size, type, and maximum inflation pressure.

3. Beads: The Tyre’s Anchor

Constructed from high-tensile steel wires enveloped in rubber, beads play a crucial role in ensuring the tyre remains securely attached to the wheel rim. They maintain the tyre’s shape and provide a snug fit, ensuring optimal performance.

4. Inner Liner: The Guardian of Air

The inner liner, made of specialized rubber, acts as a barrier, retaining the inflation pressure inside the tyre. It’s designed to be impermeable to air and moisture, ensuring consistent tyre performance.

5. Carcass Ply: The Backbone

Situated beneath the tread and sidewall rubber, the carcass ply is composed of textile fiber cords embedded into the rubber. This layer bestows the tyre with its shape, flexibility, and strength, ensuring it can withstand the pressures of the road.

6. Belt: The Distributor of Pressure

Comprising steel cords, the belt is strategically placed between the carcass and the tread. It reinforces the tyre, ensuring even distribution of pressure and enhancing the tyre’s overall durability.

7. Cap Ply: The Enhancer of Stability

Present in select high-speed tyres, the cap ply is sandwiched between the carcass and the tread. This layer amplifies the tyre’s durability and stability, especially during high-speed ventures.

Materials Used in Tyre Production:

Steel: Leveraging high-strength steel from the steel industry, it serves as the foundational material for steel belts and bead cores.

Chemicals: Incorporating synthetic rubber and other chemical industry derivatives, these materials aim to reduce wear, amplify grip, and extend the tyre’s lifespan.

Natural Rubber: Harvested from rubber trees, this material undergoes processing into solid bales, ready for transportation and storage.

Textiles: Harnessing materials like rayon, nylon, polyester, and aramid fibers from the textile industry, these components reinforce the overall structure of the tyre.

The Production Process:

The creation of a tyre is an intricate dance of sourcing premium materials, crafting individual components, assembling the tyre, undergoing the vulcanization process, and finally, rigorous quality control checks to ensure perfection.

A tyre is a symphony of various components and materials, harmoniously working together. Each part, no matter how small, plays a pivotal role in ensuring our safety and enhancing vehicle performance. With the continuous evolution of tyre technology and relentless innovation, the tyres of today stand as testaments to human ingenuity, offering unparalleled efficiency, durability, and safety.